TECHNOLOGY

We introduce DN Automotive’s technology shown in the best batteries.

-

TECHNOLOGY

-

General Knowledge of Batteries

-

Car Battery

Car Battery

DN Automotive's world-class products

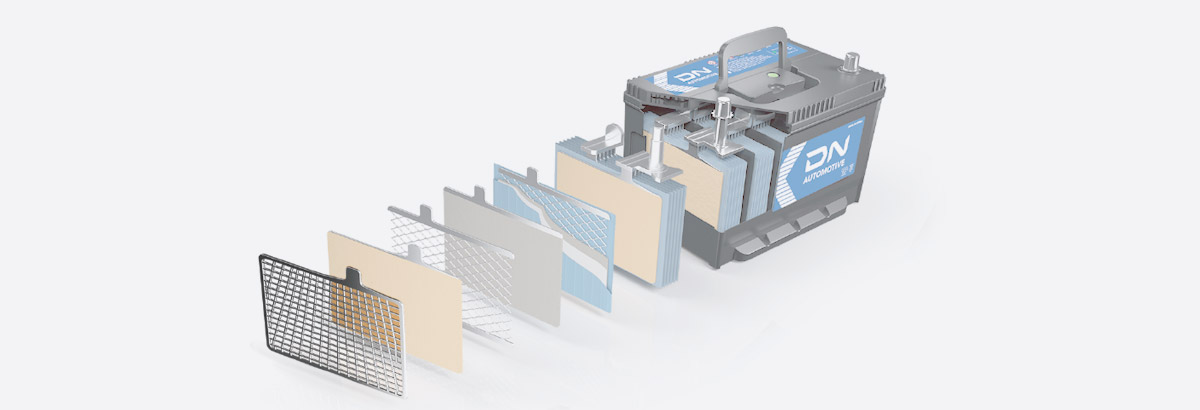

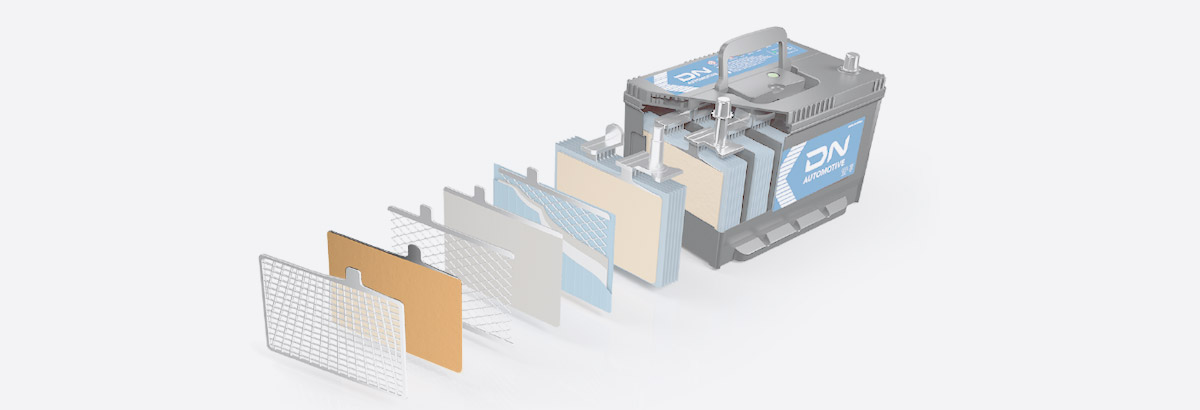

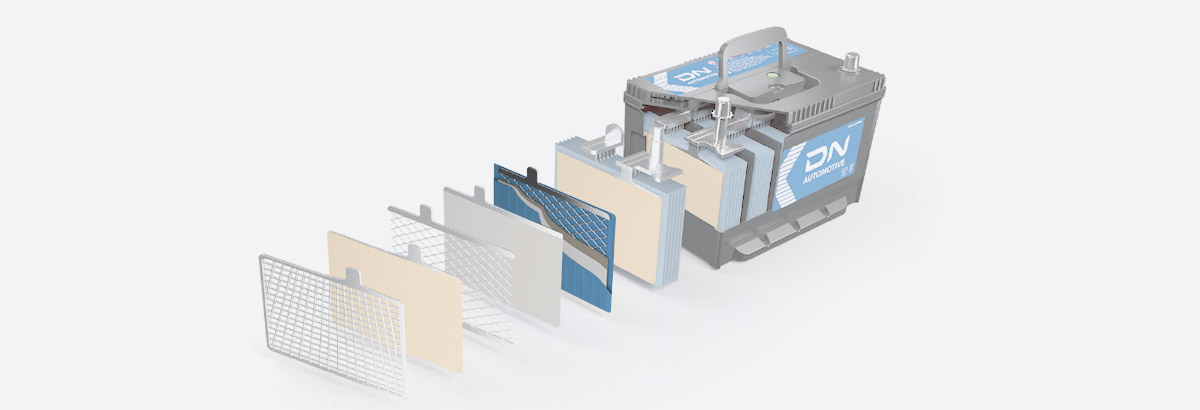

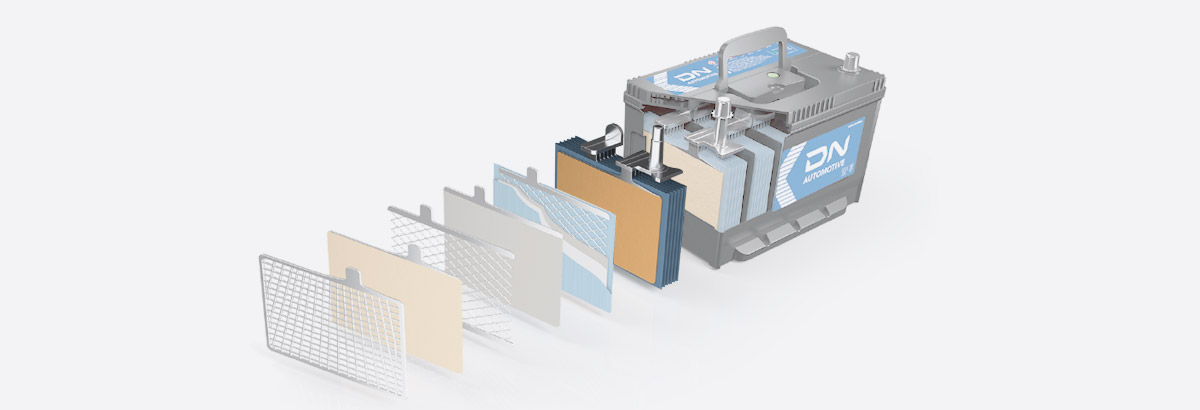

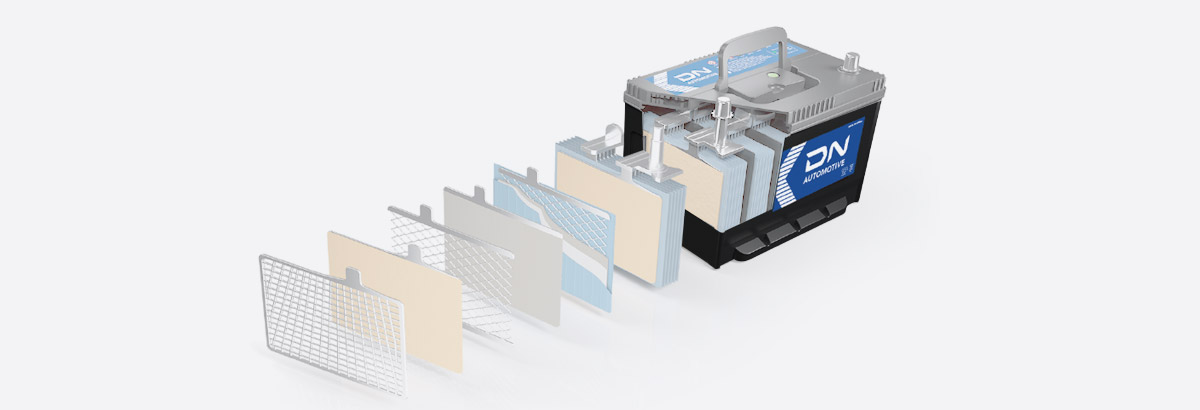

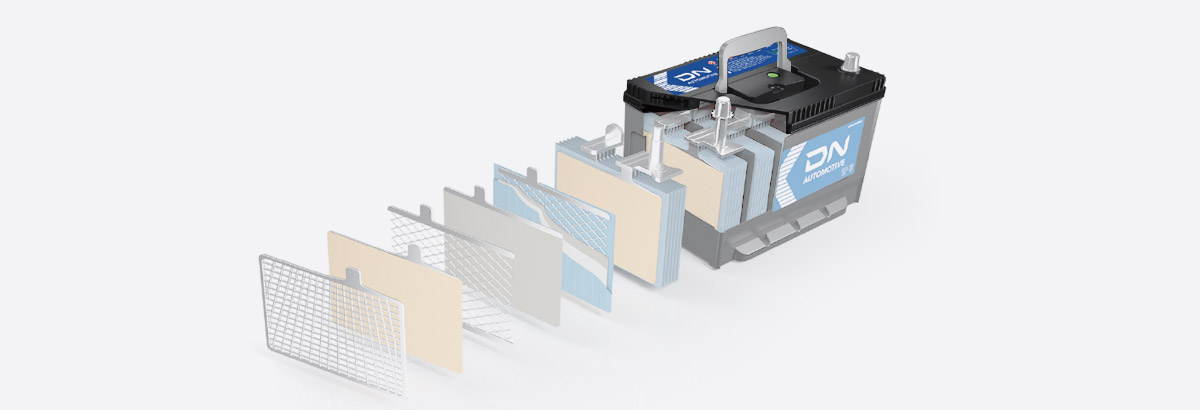

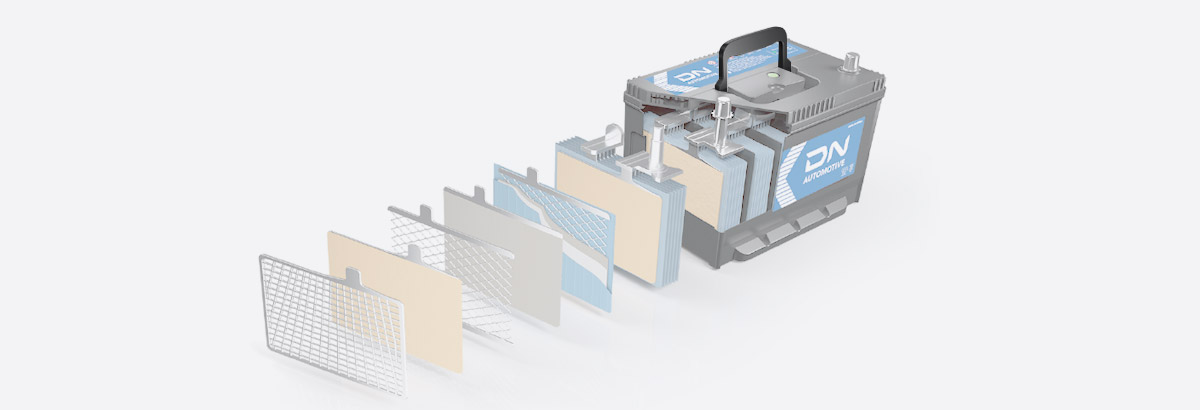

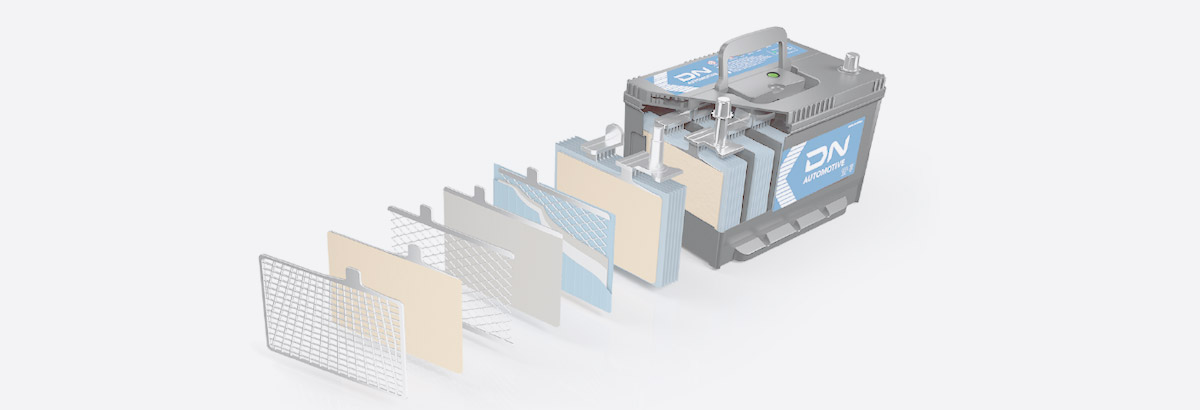

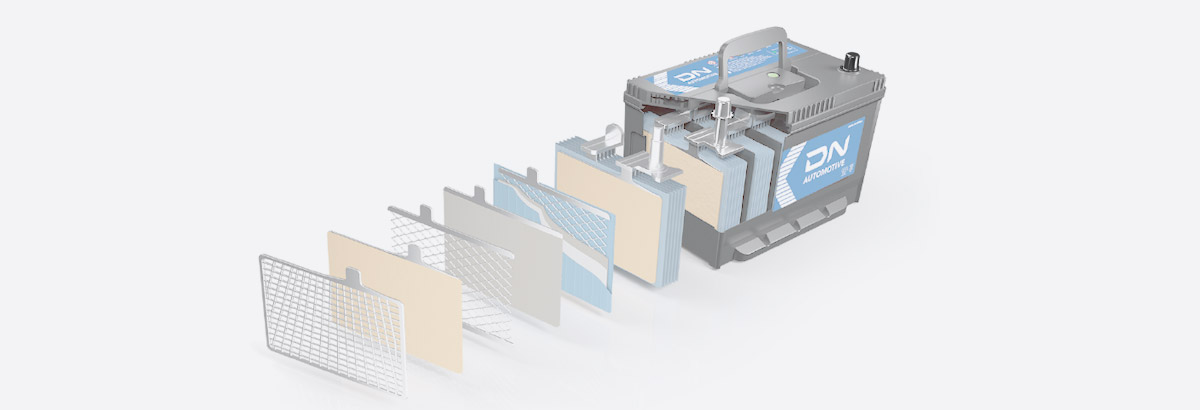

Battery Structure

-

GRID

A lead alloy board that supports active material and conducts generated electricity.

-

Positive Plate

When active material is applied on the positive grid.

-

Electroseparator

Placed between the positive and negative plates to prevent short-circuits due to direct contact. In particular, the envelope electroseparators wrap the negativeplates to prevent short-circuits with the positive plates due to the active material.

-

Electrolyte

The electrolyte causes the positive and negative pole plates to react and generate electricity, and also acts as an electrical conductor.

-

Active Material

A material that reacts with sulfuric acid to charge and discharge.

-

Negative Plate

When active material is applied on the negative grid.

-

Pole Plate Group

The electromotive force per cell is 2V. Voltage is kept steady regardless of the size or number of pole plates.

The 12V battery used for cars has 6 pole plate groups connected in a series in the container.

A group of pole plates welded to the strap, stacked in order of a positive pole plate, separator, and negative pole plate.

-

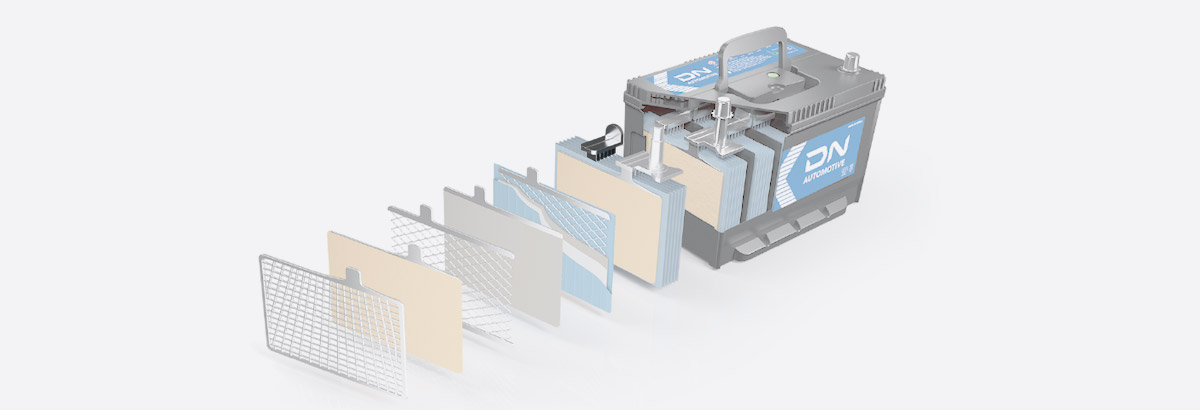

Container

It is separated internally by walls

(12V →6 divisions / 6V →3 divisions) and the bottom of the container is attached with an inner layer.A container which is usually made of plastic contains an electrolyte and the pole plate group.

Other Parts

-

Main Cover

A part that covers the top of the container to prevent electrolyte in the battery from leaking.

The main cover has filling holes to fill electrolyte, and return holes to release gas and steam.

-

Final Cover

A part that spreads over the top of the main cover

The gas and steam emitted through the return hole are separated through a labyrinth structure. The sulfuric acid steam is returned to the battery, and gases (hydrogen, oxygen) are released through the vent hole.

-

Flame Arrester

Equipment installed on the inside of the final cover for anti-explosive functions.

The released gases (hydrogen, oxygen) are flammable. Before they are released through the vent hole, the flame arrester, made of a dense bubble structure, decreases the cross-section areas to prevent the explosion.

-

Indicator

Equipment installed on the top area of the main cover to show the status of the battery

- Green : Normal, charged 50% or higher

- Black : Charging required, charged 50% or lower

- White : End of life (B/T replacement)

SLI Function

-

Function to Supply Surplus Energy in the Vehicle

In driving, the charging device usually supplies power. However, when the engine is idle, the battery acts as an aid by partially supplying power. Battery consumption is especially high when the vehicle frequently stops and goes in an urban area. If the charger is broken, the battery supplies all of the power required by the vehicle.

-

Stabilization of Electric Device

: (Protection of Electric Devices Against Overvoltage)If overvoltage occurs in electric devices, a critical short-circuits failure may occur in the electric circuit. The battery absorbs the overvoltage to alleviate the shock.