TECHNOLOGY

We introduce DN Automotive’s technology shown in the best batteries.

Processing Line

We produce the best products with

perfect process designed by top professionals.

-

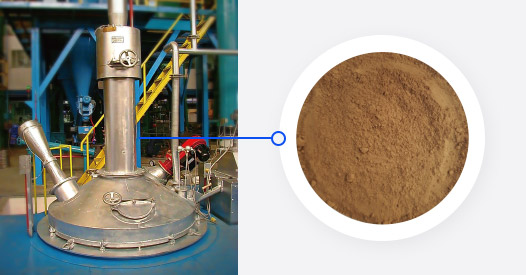

Step 1

Lead Oxide

- Special Barton pot process results in spherically shaped particles of

lead oxide and having 50% of its weight less than 4.5 microns

- Special Barton pot process results in spherically shaped particles of

-

Step 2

Strip Rolling

- Over 90% slab reduction rate

- Excellent mechanical properties, fine and uniform strip

- Anti-corrosion alloy

-

Step 3

Strip Punching

- Full Framed Grid constrains the active material and provides mechanical strength

- Reduction of Internal Resistance

-

Step 4

Pasting

- Double-sided pasting for minimizing corrosion of grid

- Strong adhesion between grid and paste

-

Step 5

Curing

- Even plate quality by vertical loading

- Optimal particle size for battery performance & lifetime

- Advanced adhesion and cohesion of plate

-

Step 6

Assembling

- Plate quantitly & weight measuring system

- Total inspection for all batteries

-

Step 7

Formation

- Multi-step charging resulting in dynamic charging capability and

less self-discharge rate - Optimized charging temperature management system

- Multi-step charging resulting in dynamic charging capability and

-

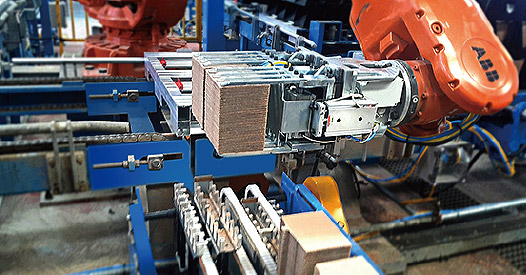

Step 8

Finishing Process

- Electrolyte cooling system &

Inspection by High Rate Discharge(HRD) - Laser marking System & Robot Packaging system

- Storage in Automatic Warehouse for Shipping

- Electrolyte cooling system &